Choose your preferred biomaterial

Xilloc offers a choice of excellent long term implantable biomaterials to meet your needs.

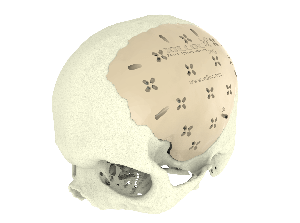

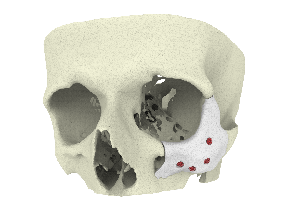

PEEK

PEEK is a high performance polymeric biomaterial that offers a superior combination of high strength, stiffness and toughness. Together with its excellent biocompatibility this makes PEEK ideally suited for patient-specific implants. It is mainly used for cranial/facial reconstructions and augmentations. Advantages of PEEK are:

- Mechanical properties comparable to bone

- Excellent biocompatibility

- Can be modified interoperatively

- Compatible with CT, MRI and radiation therapy

- Inlay implant to mimic bone thickness and restore intercranial pressure

- Autoclave (steam) sterilisation and re-sterilisation

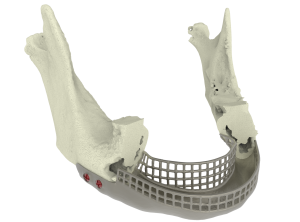

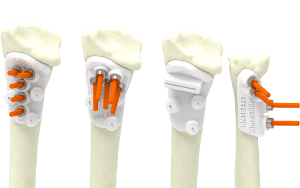

TI6Al4V

This titanium alloy (Ti-64) is a commonly used alloy in load-bearing medical applications because of its strength, low weight and excellent biocompatibility. Using 3D Printing (Selective Laser Melting) to produce patient-specific implants from TI6Al4V creates the possibility of adding porosity or lattices throughout the material and allows virtually unlimited shape complexity. It is mainly used for mandible and extremity reconstructions and custom osteosynthesis plates. Advantages of 3D printed titanium are:

- High strength, so the implant can be made slender

- Excellent biocompatibility, osteoconduction and suspected antibacterial properties

- Possibility to make porous or apply a lattice structure (for osseintegration)

- Autoclave (steam) sterilisation and re-sterilisation

PA2200

PA2200 is a 3D printed polyamide allowed for short term use. It is therefore very suitable for surgical cutting/resection/drill guides or fitting templates in any part of the body. It can also be used to 3D print anatomical models for complex surgical planning that can be sterilised and taken into the operating room. Can be steam sterilised. Disposable.

CT-Bone®

CT-Bone® is not yet available. CT-Bone® is a 3D printed calcium phosphate that unifies with the patient’s bone. It can be used for bony augmentations (non-load-bearing) and is converted into real bone in the patient. Because it is 3D printed it can be made into complex shapes with controlled porosity. Autoclave (steam) sterilisation. |

For more material details you can contact our biomedical engineers.