HeadLines

At Xilloc we are dedicated to provide the highest quality in customized products for our customers. Within our young, ambitious company, many things are happening and considerable progress is made all the time. In this fourth edition of our HeadLines , allow me to share with you our latest achievements and other interesting news.

If you would like to have more frequent updates, you can like the Xilloc Facebook page.

3D printing @ Xilloc

Besides 3D printing for medical we now also 3D print for industrial applications

The main topic of this newsletter is 3D printing. This production technology is perfect for patient-specific implants in particular, but is in general also ideal for manufacturing complex industrial parts. At Xilloc we have gathered considerable knowledge about 3D printing in polymers (cutting guides), metals (titanium implants).

Furthermore, we are expanding our medical 3D printing capacity with new 3D printing machines to offer 3D printed (bio)polymers, calcium phosphate bone implants (CT-Bone) and titanium implants.

3D printing real bone: CT-Bone

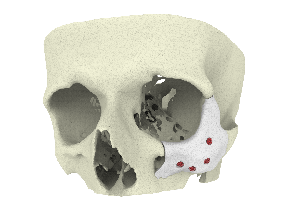

3D printed CT-Bone implant for zygoma augmentation

Early next year we will start 3D printing personalized ceramic implants to augment the skeleton, called CT-Bone. CT-Bone is made from calcium phosphate and has a strength comparable to trabecular bone. It is therefore indicated to use for non load-bearing augmentation implants (e.g. to augment the zygoma, the mandible angle, the skull, etc.). It has been demonstrated to be converted into real bone by the patients bone cells. The main advantage of CT-Bone is that it requires no heat treatment (sintering) after 3D printing. Such a heat treatment causes significant shrinkage and reduces the resorbability. Unlike hydroxyapatite, which is non-resorbable, CT-Bone is invaded by bone tissue, bone marrow and bone resorbing osteoclasts. Without the need for sintering, CT-Bone can be designed to perfectly match the patient’s anatomy and can be accurately 3D printed to fit perfectly, thereby optimizing the bone-implant interface.

4 new professional 3D printers from EOS

Maikel Beerens shaking hands with Dr Hans Langer in front of the EOS M 400

Xilloc invested in four 3D printers from the renowned German manufacturer EOS, who is the global technology and quality leader for high-end Additive Manufacturing (AM) solutions. Amongst the four machines is the EOS M 400, one of the largest metal machines currently available on the market. Together with Brightlands Chemelot Campus and with the financial support of the Province of Limburg, a wider range of unique 3D printing services are now available.

With these impressive additions, Xilloc has established an advanced manufacturing facility, which also includes state-of-art automated milling machines.

Move to Brightlands campus

Recently, Xilloc moved to Brightlands Chemelot Campus where it has access to 600 m²; ample space to accommodate its rapid growth and team expansion. For the campus, this is another important step towards the creation of an Additive Manufacturing ecosystem. Earlier this year, Brightlands Materials Center has been established, including investments in “PhD capacity” for 3D print material technology. The campus is a fast growing hub for 3D printing in the Netherlands and across its borders, with Xilloc as a spearhead.

Recently, Xilloc moved to Brightlands Chemelot Campus where it has access to 600 m²; ample space to accommodate its rapid growth and team expansion. For the campus, this is another important step towards the creation of an Additive Manufacturing ecosystem. Earlier this year, Brightlands Materials Center has been established, including investments in “PhD capacity” for 3D print material technology. The campus is a fast growing hub for 3D printing in the Netherlands and across its borders, with Xilloc as a spearhead.

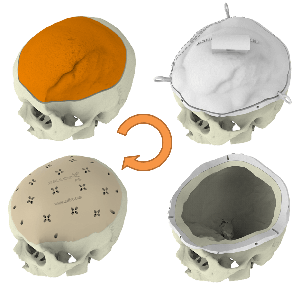

One-stage meningioma reconstruction

We developed a new and easy method to resect and reconstruct an intraosseous meningioma in one operation. Using CT imaging, the surgery is planned together with the surgeon and the resection margin is defined. We then create a unique 2-piece cutting guide that allows accurate resection. Following the resection, a perfectly fitting reconstruction implant can be placed in the resected area. This implant is equipped with XSuture for easy suturing and InterFix for fast and secure tangential fixation. This procedure allows the resection of such a meningioma and reconstruction in only one surgery instead of two, saving time and money while helping the patient in the most optimal way.

We developed a new and easy method to resect and reconstruct an intraosseous meningioma in one operation. Using CT imaging, the surgery is planned together with the surgeon and the resection margin is defined. We then create a unique 2-piece cutting guide that allows accurate resection. Following the resection, a perfectly fitting reconstruction implant can be placed in the resected area. This implant is equipped with XSuture for easy suturing and InterFix for fast and secure tangential fixation. This procedure allows the resection of such a meningioma and reconstruction in only one surgery instead of two, saving time and money while helping the patient in the most optimal way.

4th anniversary and team expansion

In august, we celebrated our fourth anniversary. We are proud that our surgeons and patients are very satisfied with our patient-specific products and our personal service. We will continue to provide our high quality products to a growing number of surgeons, as well as assist other companies with high quality 3D printed parts to improve and expand their business. To support that, we have expanded our team with several new faces. Check our facebook page to meet them!

In august, we celebrated our fourth anniversary. We are proud that our surgeons and patients are very satisfied with our patient-specific products and our personal service. We will continue to provide our high quality products to a growing number of surgeons, as well as assist other companies with high quality 3D printed parts to improve and expand their business. To support that, we have expanded our team with several new faces. Check our facebook page to meet them!

Research in personalized patient products and/or 3D printing

Xilloc is already actively involved in several funded research projects and is still open to collaborate in funded projects in the field of customized patient care or 3D printing. If you have an idea or project and you would like a passionate SME involved, do not hesitate to contact us.